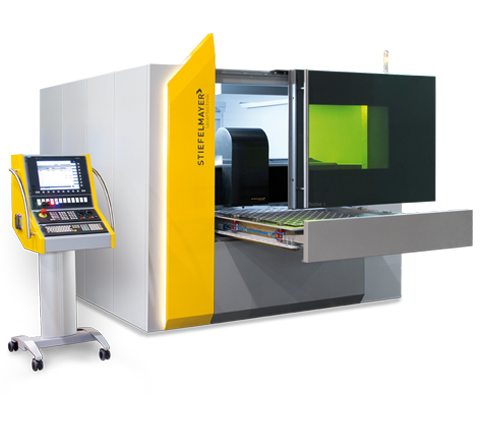

» Laser cutting with the STIEFELMAYER effective S »

» STIEFELMAYER effective S »

Precision and dynamics in a new dimension

The right choice for the highest precision requirements for the production of laser cutting parts. This machine combines state-of-the-art technologies into a unit with previously unknown possibilities for laser cutting.

Sample service: Samples are always more expressive than any technical machine data, for in the end precision and productivity are what counts.

State-of-the-art laser technology

Fibre lasers achieve a high level of absorption in metallic materials, they have an electrical-optical efficiency of approx. 30 % and offer outstanding beam quality. These characteristics allow cutting of metal alloys from steel, aluminium and copper.

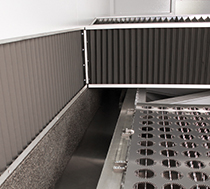

Solid granite basis

The granite bodies of the longitudinal axes rest on a steel construction which was annealed to eliminate stresses. The large mass of the granite axes and the specific properties of the granite, such as long-term stability, vibration damping and low temperature expansion, form a solid and highly precise basis for the dynamically moving parts of the machine.

Lightweight construction in carbon technology

Achieving the shortest possible production time for the manufacturing of complex, delicate parts requires the highest level of dynamics which is achieved through a reduction of the moved masses. On the STIEFELMAYER effective S, this was implemented by using lightweight carbon constructions for the moving Y-axis and its attachment parts.

Dynamic drive technology

No other drive technology than linear motors is better suited for achieving the required dynamics and precision. It generates a direct, straight movement, allowing vibration-free transmission of forces into the moving parts of the machine. This enables the highest level of path accuracy with the highest level of dynamics. In addition to this, linear motors are mostly free from wear.

Technical data

Beam source: fibre laser

Laser output: 1 kW

Suitable materials and thicknesses:

| mild steel, stainless steel: | 3 mm |

| Aluminium: | 2 mm |

| Brass: | 3 mm |

| Copper: | 2 mm |

| Cutting gases: | nitrogen or oxygen |

Electric power consumption of the complete machine in operation: 8 kW to 12 kW

CNC control: 840D SL

Guiding machine: welded steel construction with granite axes, moving parts made of lightweight carbon

Drives: X/Y-axis linear motors, Z-axis circulating ball screw with servo motor

Guides: backlash-free preloaded circulating ball bearings

Dimensions: Footprint: approx. 29 m²

Width x depth x height: 4500 mm x 6600 mm x 2358 mm

complete installation area of the machine

with extended table incl. laser, control cabinet, extraction, cooling unit

Processing table: 1250 mm x 1250 mm

Axis paths: X 1260 mm, Y 1260 mm, Z 50 mm