» STIEFELMAYER effective M »

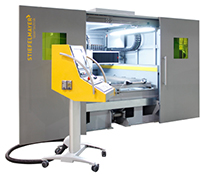

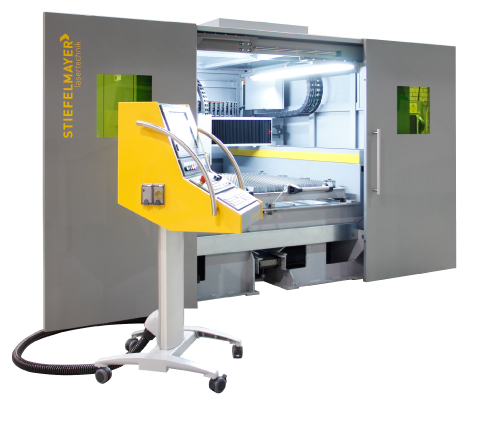

» Laser cutting with the STIEFELMAYER effective M »

The versatile machine, not only for sheet metal.

The all-rounder offers a table size of 1500 mm x 1500 mm while the large sliding doors provide convenient access. The table can be extended to facilitate loading and unloading of parts.

This versatile machine allows laser cutting not only of sheet metal and material strips, but also of formed components or parts in fixtures. The machine concept with its high feedthrough and long Z-axes offers an efficient and cost-saving alternative to 5-axis 3D processing for many tasks.

The STIEFELMAYER effective M combines state-of-the-art technologies into a unit with previously unknown possibilities for laser cutting.

Sample service: Samples are always more expressive than any technical machine data, for in the end precision and productivity are what counts.

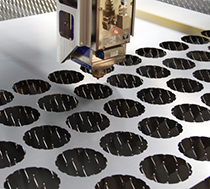

State-of-the-art laser technology

Fibre lasers achieve a high level of absorption in metallic materials, they have an electrical-optical efficiency of approx. 30 % and offer outstanding beam quality. These characteristics allow cutting of metal alloys from steel, aluminium and copper.

Drive technology

The axes are guided with pre-tensioned circulating ball bearings and are moved by backlash-free circulating ball threaded spindles. A proven technology from tool machine engineering was successfully implemented in the design of the STIEFELMAYER effective M.

Technical data

Fibre lasers achieve a high level of absorption in metallic materials. With very high beam quality, this significantly improves the process efficiency and yields considerably higher cutting speeds than with CO2 lasers. Other advantages result from the simple and precise beam guiding from resonator to cutting head. Expensive maintenance, adjustment and cleaning of the mirrors is not necessary. On request, CO2 lasers can also be integrated into the 5-axis machine.