» NEW » Automated production of bonded stacks with laser-cut electrical steel »

The sophisticated work required to develop electric motors for EVs is also impacting other electric motor industries and accelerating the further specialisation of electrical drive systems. This is necessarily leading to greater variance and therefore to smaller lot sizes. These kinds of volume scenarios are challenging for electric motor manufacturers, since conventional stack stamping is not economical for the production of prototypes and short runs.

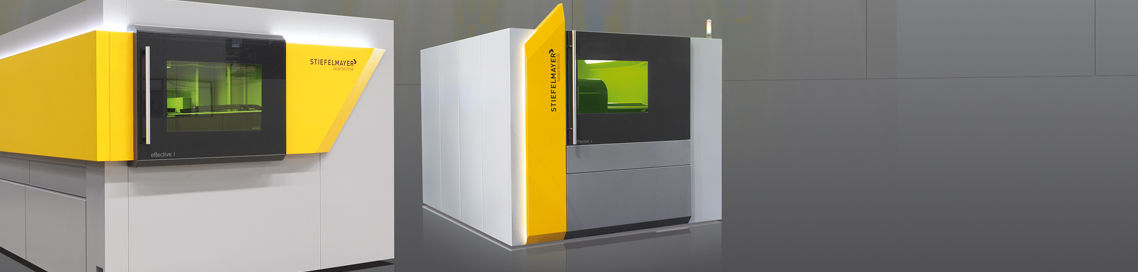

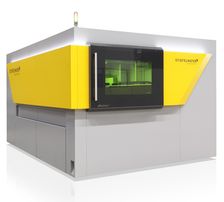

» Laser cutting machine effective L »

» Laser cutting with the STIEFELMAYER effective L »

In the STIEFELMAYER effective L, state-of-the-art technologies and the unique table system combine to form a machine with the highest level of precision, dynamics and productivity.

» Laser hardening machine HC5 »

» HC5 stands for hardening and cladding with 5 axes »

STIEFELMAYER-Lasertechnik – we did not invent these technologies, but we created something special with it: STIEFELMAYER HC5.

» NEW » Challenge and solution in production »

Challenge:

Automated, flexible and cost-effective production of bonded rotor and stator stacks.

Solution:

Combining the STIEFELMAYER ‘effective’ laser cutting machine with the PMOS Püttmer stacking system. Ensuring the automated production of laser-cut, bonding varnish-coated electrical steel stacks. A milestone in the production of rotor and stator stacks!

» Laser cutting machine effective S »

» Laser cutting with the STIEFELMAYER effective S »

Precision and dynamics in a new dimension. The right choice for the highest precision requirements for the production of laser cutting parts. This machine combines state-of-the-art technologies into a unit with previously unknown possibilities for laser cutting.

» Contract laser cutting »

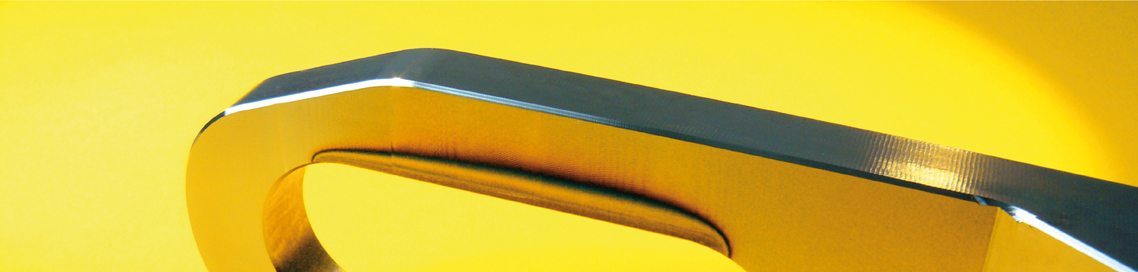

» Highest cutting quality through laser machining on the STIEFELMAYER effective »

» For prototypes, pilot series parts and small series

» For laser parts with highest precision and high quality surfaces

» Provision of customer material possible for exceptional requirements

» Laser welding machine LW2 »

» Laser welding with the STIEFELMAYER LW2 »

The laser welding machine for high-precision electrical steel packages.

For the production of small series in electrical engineering, the laser technology can be used in different variants, each with technological advantages.

» Contract laser hardening »

» Quality advantages through laser hardening on the STIEFELMAYER HC5 »

» Targeted laser machining with lowest possible heat input allows partial hardening of functional surfaces on the component

» Heat treatment with particularly low warping, even for hard-to-reach hardening zones